The Interflex Advantage

A Legacy of Innovation, Precision, and Service

With over 30 years of engraving expertise, Interflex delivers more than just precision rolls—we provide proven knowledge that helps our customers run smarter, faster, and more efficiently.

Decades of experience mean we understand the challenges of the pressroom and have the insight to recommend solutions that improve consistency, reduce downtime, and maximize print performance.

Our Manufacturing Process

Quality & Precision Crafted Into Every Roll

At Interflex, precision isn’t just part of the job—it’s our promise. Every roll and sleeve we produce follows a carefully controlled process designed to deliver consistent, high-quality engravings that keep your presses running at their best.

Step 1: Incoming Inspection

Step 2: Surface Preparation

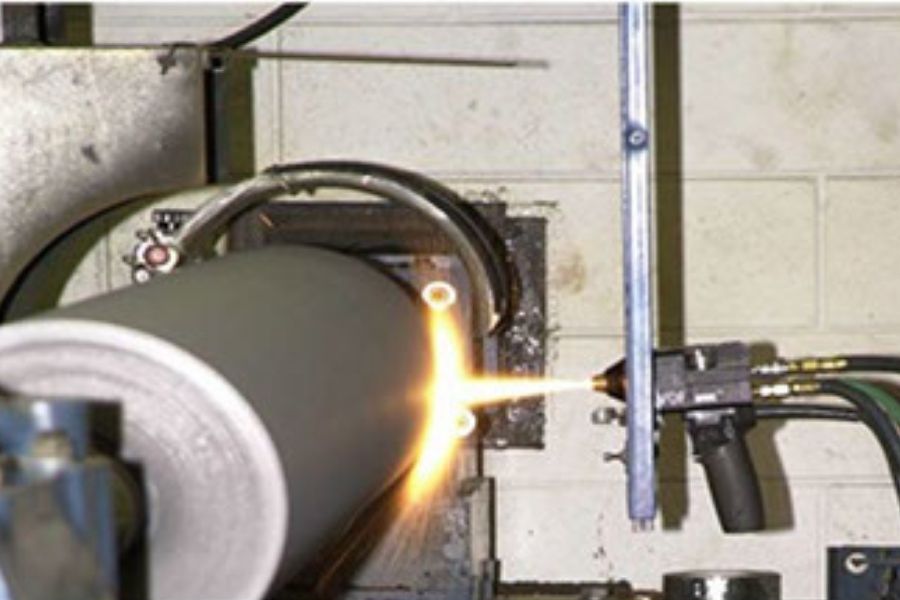

Step 3: Ceramic Coating Application

Step 4: Mirror Polishing

Step 5: Laser Engraving

Step 6: Final Quality Control

Every engraved roll undergoes a rigorous series of pass/fail inspections to guarantee it meets performance expectations before shipment.

Why Choose Interflex?

Fast Turnarounds

Your uptime is our top priority. With the largest engraving capacity in the U.S. and roll inventory on hand, we turn jobs quickly—even the tough, rush-critical ones. Customers come to us when deadlines get tight because they know we deliver. When the press is waiting, Interflex moves.

Expert Technical Support

Our Technical Sales & Service Reps are stationed across the country, ready to support you with real, hands-on experience. From audits and troubleshooting to banded test rolls and in-plant training, we make your team stronger and your process smoother. When you call Interflex, you reach people who can help you solve problems fast.

Highest Engraving Quality

Interflex engravings are built for consistency, longevity, and cleaner print. Our fiber-optic laser systems can achieve some of the tightest tolerances in the industry (.0002” TIR) to deliver uniform results, roll after roll. We offer HD™ engravings, wear indicators, and a full lineup of standard and custom engravings designed to achieve your goals.

Boutique Service Approach

We may not be the biggest—but we’re known for being the most attentive. Every project gets personal oversight, clear communication, and engravings tailored to your exact specs. You’ll always know where your roll stands because we treat your schedule like our own. It’s the kind of dependable, relationship-driven support that sets Interflex apart.

Trusted by Leading Manufacturers

Start Your Next Custom Roll Engraving with Confidence

With over 30 years of high-level service combined with the most laser engraving machinery in the USA, Interflex Laser Engravers is here to help you succeed.

Ready to Get Started?

Reach out to our Technical Team to discover how our high-definition engraving technology can elevate your production.